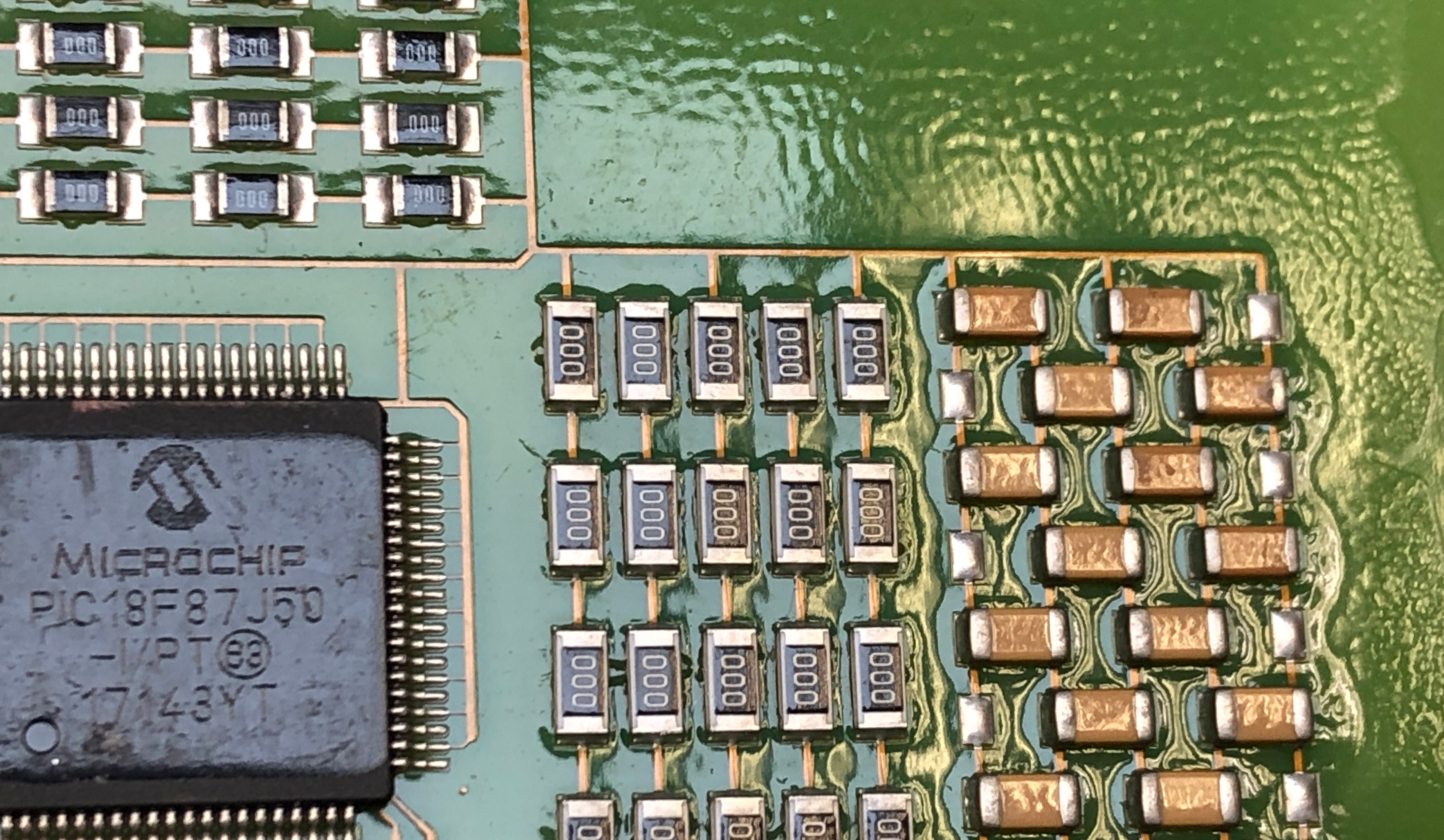

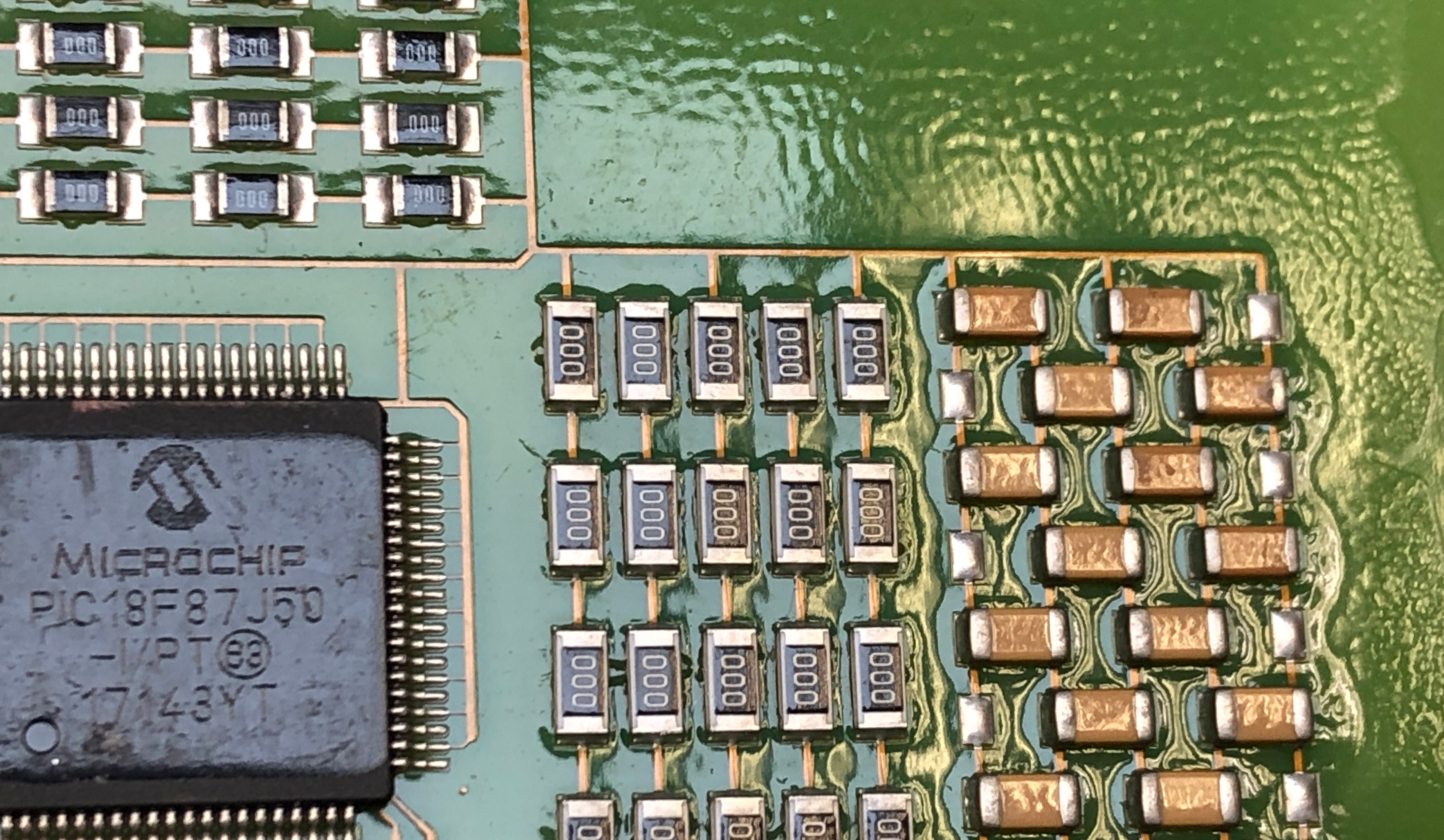

Acrylic conformal coating is recognized for its high dielectric strength and fair moisture and abrasion resistance.

Acrylic conformal coating waterproof.

Fast drying single component acrylic conformal coating.

Chemtronics konform conformal coating is used for spray dip tank and brush applications.

They re engineered for applications in aerospace marine manufacturing electrical equipment instrumentation and data communication.

Even if applied heavily most coatings are semi permeable so allow some amount of moisture through.

While conformal coatings can offer a moisture resistant layer of protection most cannot be considered waterproof.

And similar electronics from the incursion of water is an essential responsibility of parylene xy conformal coating.

Conformal coating can however prevent current leakage or corrosion due to ambient moisture.

Types of conformal coating.

Formulated with reduced xylene and toluene concentration to be fully compliant with gb30981 2020.

Below are descriptions pros and cons of each.

Pcb conformal coating service high temperature waterproof pcb coatings.

The other commonly available types are acrylic or urethane conformal coating while they will also work they are not as durable and can not be reworked as easily.

Humiseal 1b31 ltx conformal coating is.

Acrylic coatings are easily and quickly removed by a variety of solvents often without the need of agitation.

Specifically designed to protect against the effects of moisture corrosive environments and dirt.

Use konform conformal coating for maximum pcb protection.

Acrylic conformal coating 27 parylene process 25.

Urethane resin ur epoxy resin er acrylic resin ar silicone resin sr and parylene xy.

What generally distinguishes acrylic coating from other resins is ease of removal.

While many varieties of coating exist including a few specialty types there are five main categories based on the substances chemical makeup.

Waterproofing drone electronics conformal coating tutorial you can prolong the life of electronics in a quadcopter with waterproofing the most common method is conformal coating.

Silicone conformal coatings generally contain xylene as a solvent make sure that you use the product in a well ventilated area it smells nasty and if you breathe in too much of the.

It helps prevent components from moisture and chemical damage when flying in extreme conditions.

Discover if parylene coating is enough to make your product waterproof.